ANSI Z89.1 helmets SM-926 / SM-936

-

- Products

- ANSI Z89.1 helmets SM-926 / SM-936

Solid safety helmet

ANSI Z89.1 helmets SM-926 / SM-936

Certification

Introducing Parkson Safety ANSI Z89.1 helmets SM-926 and SM-936 – the ultimate choice in head protection for those working in industrial, factory, mining, and steel environments. These helmets offer a robust design and are made from durable PP material, ensuring a higher level of protection and a longer-lasting product.

The SM-926 model features six air vents for increased ventilation, while the SM-936 is designed without vents, providing electrical insulation. Both helmets are certified to ANSI Z89.1 and CE EN397 standards, guaranteeing quality and safety compliance for users.

With universal 30mm side slots, these helmets can accommodate visor bracket Ref: H-867 or helmet mounting earmuffs EP-167 or EP-187, providing additional protection against noise and debris. A U-shaped design at the back serves as a rain gutter, preventing water from dripping onto the neck area.

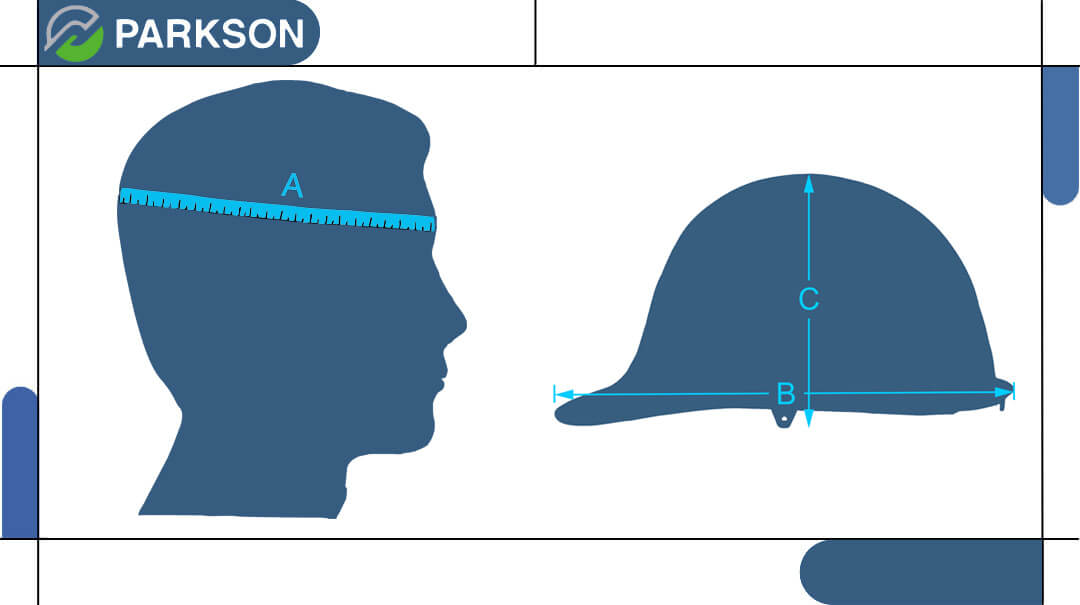

Choose from 4 or 6-point suspension options for a customized fit, with options including PE plastic or nylon webbing, and pinlock, press ratchet, or nob ratchet adjustments for headsize 55-62cm.

Key features of the SM-926 and SM-936 helmets include their impact-resistant design, with bumps on the top providing enhanced protection, and their perfect fit for maximum wearing comfort. These helmets are suitable for all-day wear, providing the ultimate protection for workers and visitors alike.

Customize your helmet with optional accessories such as visor brackets, suspensions, earmuffs, chin straps, and visors. Trust Parkson Safety’s ANSI Z89.1 Helmets SM-926 and SM-936 for reliable head protection and superior comfort in demanding work environments.

Optional:

| Model | SM-926 / SM-936 |

| Weight (include CS-2 suspension) | |

| Head Sizing (A) | |

| Length (B) | |

| Height (C) | |

| Origin | Taiwan |

| Certification | CE EN12492 standard |

Most people mistaken between the use of industrial safety helmet with bump cap. Due to bump cap light weight and more fashionable design, most people prefer the use of bump cap over safety helmet. But bump cap can not replaced as safety helmet. Bump cap is tested against European standard CE EN812 although there are still impact and penetration testing, but bump cap are intended to protect end user head from hitting stationary hard objects such as truck driver use when entering building with low ceiling or hanging objects.

For safety helmet it is intended to protect end user head against falling objects. International standard such as CE EN397 and America standard ANSI Z89.1 will cover physical and performance requirement for industrial safety helmet use in occupational health and safety.

Safety helmet usually consist of a front sweat band to increase comfort, chinstrap to secure helmet to head and adjustable harness where end user can adjust sizing to head. Parkson Safety offer 2 type of bump cap, Refer to SM-903, it is similar style to safety helmet where there is an internal adjustable harness and sweat band, but no chin strap available. Another style is our sports style bump cap such as Ref:SM-913 where it consists of fabric outer over an inner ABS shell with EVA foam for shock absorption and with back velcro adjustable.

Parkson Safety offer traditional style safety helmets with a front peak to keep out of sun and rain. We also offer models with ventilation system to increase airflow such as SM-924. Full brim helmet Ref:SM-905 are to provide better protection against rain and sun but have disadvantage with its big sizing in transportation and storage. Climbing style helmet offers better visibility are also becoming increasing more popular in current market trend.

Parkson new launch model SM-919 are climbing style helmet certified under CE EN397 and ANSI Z89.1. Our latest development SM-909 are certified under CE EN12492 as Climbing and mountaineering helmet. The main differences between CE EN12492 and CE EN397 where CE EN12492 required a chinstrap strength greater than 50kg, where the helmet needs to secure on the head in the case of a fall.

Whereas CE EN397 required a chinstrap strength no more than 25kg, to reduce the risk of strangulation upon impact on the helmet. It is essential to determine the intention of use and the risk involved to select the most suitable products for personal safety protection. We recommend to access SATRA explanation on EN12492 testing via EN 12492: 2012 – Helmets for mountaineers (satra.com)

#

Parkson Safety provide professional ODM service to worldwide customers by supplying products under private branding. We have vast experiences and knowledge in customized branding.

As our products are for personal safety purpose, most countries have local safety regulation. We worked with INSPEC, SGS, DIN CERTO, CRITT, BSI GROUP as example for certification of products. We have tech staff to perform secondary CE cert application as support. If client have special testing requirement, we work with local test lab such as SGS Taiwan for product testing.

Additionally upon confirm order, we have artwork staff help to custom design packaging artwork free of charge. We can also help to provide high quality image for advertising and also DM/Flyer for local distribution.

Our sales teams have vast experiences, if you have any inquiries, welcome to further discuss your requirement with us.

Our artwork staff can help to arrange digital proofs with logo on products for approval before production.

Depending on product type, for example safety spectacles/protective goggles/earmuff, these are package in polybag and then inner box and then in corrugated master carton.

Custom Pallet packing with plastic wrapping can be carter with additional charge.

For standard product products we are happy to offer few items free of charge, but freight cost needs to be cover. However, if it is a high cost product or required a lot of samples or if it is customized product, there will be sample charge apply. For shipment, we recommended client arranging reserve collection via local express service to pick up samples from us. Or we can quote with our partner express service for cost to the nominated postal address.

For standard product and are available on hand, sample lead time around 3-5 days. If samples are not available on hand or if it is customized sample, please kindly allow longer wait time.

We have ISO 9001 and are certified by Dun & Bradstreet Number:657536132

As we are selling safety protection equipment, we also have CE certification for EU market and third party test report for ANSI (US market).

No, we do not have FDA

In general our MoQ is USD10,000 per shipment mix item acceptable.

It is very welcome to advise the required qty and we will try to carter for the qty of interest. We understand a smaller trial order is required to develop trust and to test the market.

Most of our clients arrange sea shipment port to port. For urgent orders we can arrange express courier service such as FEDEX/DHL/TNT. We can also carter for air freight airport to airport and also sea shipment with to door delivery service.

Most items we do not keep stock. We produce goods base on confirm order, as most of our client arrange products with their own logo. We might have a small qty of standard product as sample.

Yes, we have customers all over the world. In some countries we might have exclusive or local distributor. Please feel to let us know of your requirement and we can direct them to you.

Understanding we are working internationally, third party inspection is welcome. We have worked with SGS/V TRUST/TESTCOO/Intertek/UL/BV. Alternatively, we can also help to provide photos of goods upon completion and offer shipping samples for checking before shipment. In some countries, it is required third party organization to issue certificate of conformity before importation, our staff have vast experiences and can offer professional assistance.

Production time depends on product type and qty, in general please allow 60days.